Product

Message

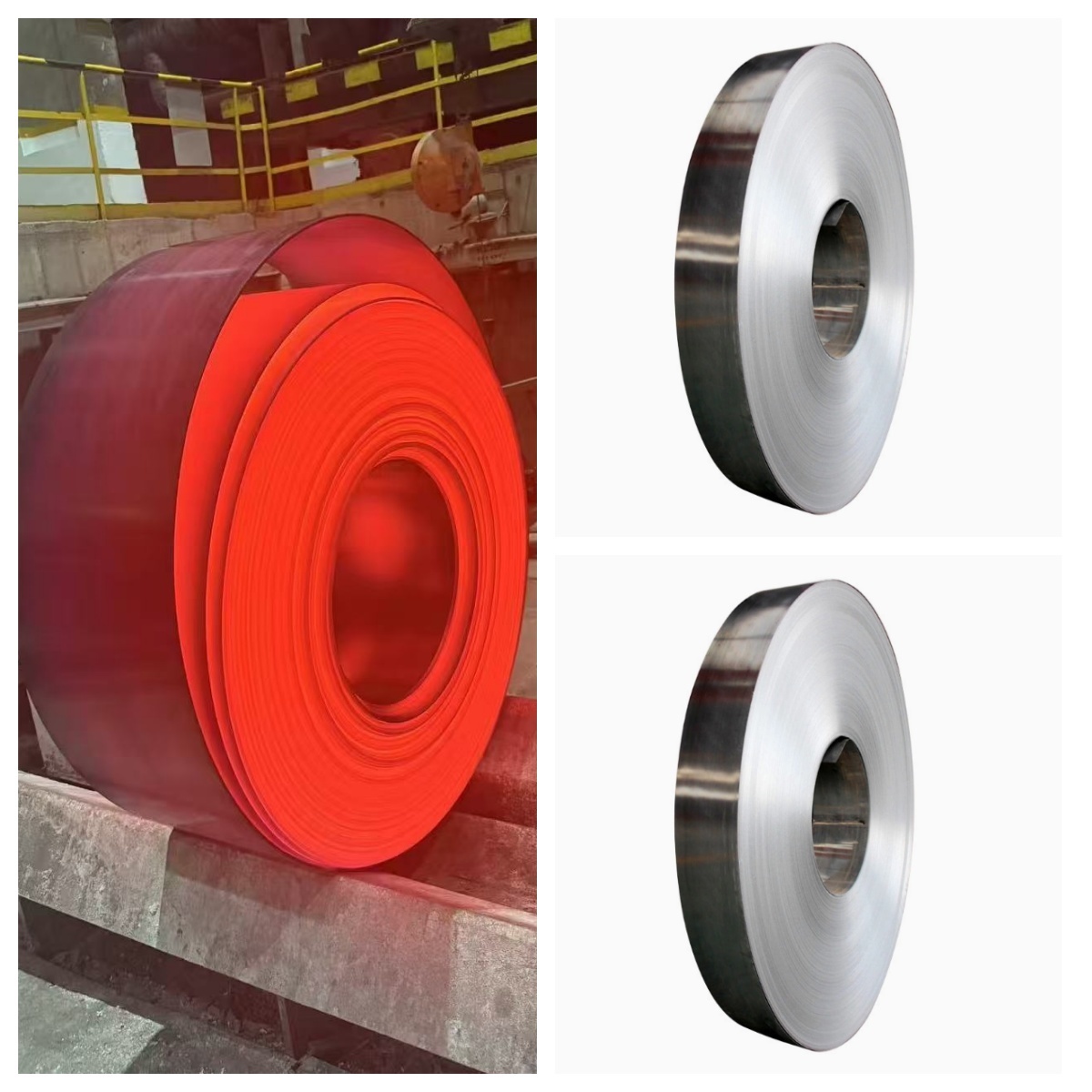

Nickel alloy Inconel 601 plate/ UNS N06601 teel bar 2.4851/alloy 601 steel strip/coil

Inconel 601 is a high-temperature alloy, mainly composed of nickel, chromium and iron, and containing elements such as aluminum and titanium. It has good high temperature resistance, oxidation resistance, corrosion resistance and mechanical properties. Chemical composition: Nickel content 61%-63%, chromium content 21%-25%, iron content 6%-10%, and also contains aluminum, titanium, silicon, manganese and other elements. Physical Properties: Density is about 8.1 g/cubic centimeter, hardness is between HB180-220. High temperature resistance: It can work at high temperatures from 1100°C to 1200°C, and has good thermal stability and thermal conductivity. Oxidation resistance and creep resistance: It can operate stably for a long time in high temperature and oxidizing environments, and has high creep rupture strength. Anti-corrosion performance: Resistant to corrosion by a variety of chemical media such as acids, alkalis, and salts. Mechanical Properties: High strength, high toughness and good plasticity. Application fields: Widely used in the manufacture of high-temperature stoves, pipes, heat exchangers, aerospace engine components, etc. Inconel 601 alloy is widely used in the petroleum, chemical, aerospace and energy industries due to its excellent properties

Category:

Corrosion resistant alloy

Email:

Inconel 601 is a high-temperature alloy, mainly composed of nickel, chromium and iron, and containing elements such as aluminum and titanium. It has good high temperature resistance, oxidation resistance, corrosion resistance and mechanical properties.

Chemical composition: Nickel content 61%-63%, chromium content 21%-25%, iron content 6%-10%, and also contains aluminum, titanium, silicon, manganese and other elements.

Physical Properties: Density is about 8.1 g/cubic centimeter, hardness is between HB180-220.

High temperature resistance: It can work at high temperatures from 1100°C to 1200°C, and has good thermal stability and thermal conductivity.

Oxidation resistance and creep resistance: It can operate stably for a long time in high temperature and oxidizing environments, and has high creep rupture strength.

Anti-corrosion performance: Resistant to corrosion by a variety of chemical media such as acids, alkalis, and salts.

Mechanical Properties: High strength, high toughness and good plasticity.

Application fields: Widely used in the manufacture of high-temperature stoves, pipes, heat exchangers, aerospace engine components, etc.

Inconel 601 alloy is widely used in the petroleum, chemical, aerospace and energy industries due to its excellent properties