Product

Message

Hastelloy C22/Hastelloy C2000/Hastelloy C4/Hastelloy X Alloy tube bar

Hastelloy C22 (N06022) Hastelloy is a nickel-based superalloy composed of nickel, molybdenum, cobalt, tungsten and other elements, with a nickel content of about 60%. It is an all-round nickel-chromium-molybdenum-tungsten alloy with better overall corrosion resistance than other existing nickel-chromium-molybdenum alloys, including Hastelloy C-276, C4 alloy, and 625 alloy. Hastelloy C22 alloy has good resistance to pitting corrosion, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidative aqueous media including wet chlorine, nitric acid or a mixture of oxidative acids containing chloride ions.

Category:

Hastelloy

Email:

1. Overview of Hastelloy C22 (N06022) Hastelloy:

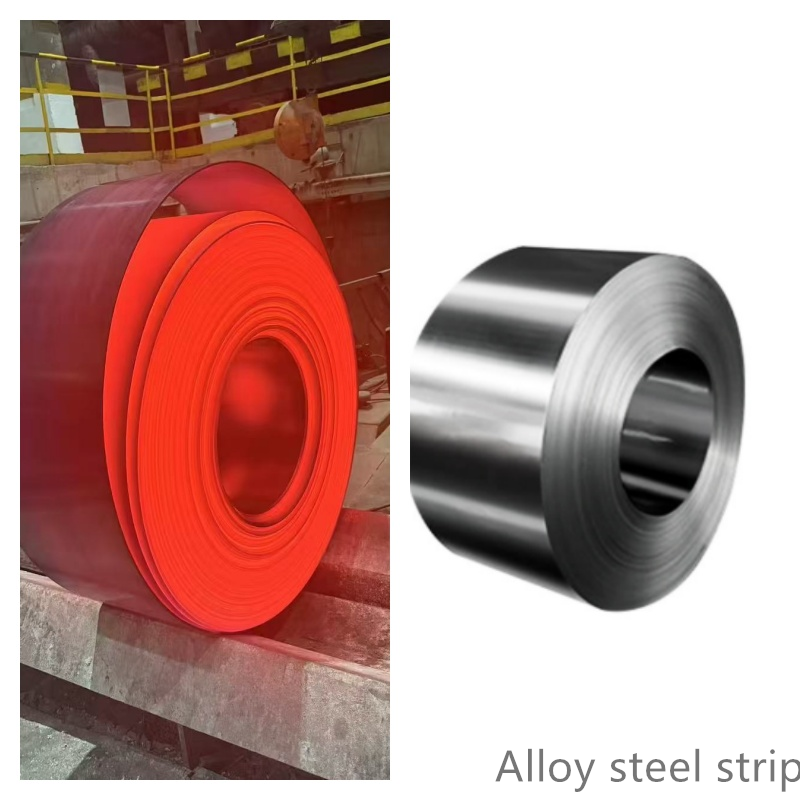

Hastelloy C22/Hastelloy C-22/UNS N06022/2.4602Plate,Roll,Steel belt,Great,Tube,Forging

Hastelloy C22 (N06022) Hastelloy is a nickel-based superalloy composed of nickel, molybdenum, cobalt, tungsten and other elements, with a nickel content of about 60%. It is an all-round nickel-chromium-molybdenum-tungsten alloy with better overall corrosion resistance than other existing nickel-chromium-molybdenum alloys, including Hastelloy C-276, C4 alloy, and 625 alloy. Hastelloy C22 alloy has good resistance to pitting corrosion, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidative aqueous media including wet chlorine, nitric acid or a mixture of oxidative acids containing chloride ions.

At the same time, Hastelloy C22 (N06022) also has ideal resistance to reducing and oxidizing environments encountered in the process. Relying on this versatile performance, it can be used in some troublesome environments, or in a variety of production purpose factories. Hastelloy C22 (N06022) alloy has exceptional resistance to various chemical environments, including strong oxidizing substances such as ferric chloride, cupric chloride, chlorine, and thermally polluted solvents. Liquids (organic and inorganic), formic acid, acetic acid, acetic anhydride, seawater and salt solutions, etc. Hastelloy C22 (N06022) alloy has the ability to resist the formation of grain boundary precipitation in the welding heat affected zone, which makes it suitable for many chemical process applications in the welded state.

2. Chemical composition of Hastelloy C22 (N06022): See Table 1-1.

Table 1-1

|

C≤ |

Si≤ |

Mn≤ |

P≤ |

S≤ |

Cr≥ |

Ni≥ |

Mo≥ |

Cu≤ |

|

0.015 |

0.08 |

0.50 |

0.025 |

0.010 |

20.0-22.5 |

more |

12.5-14.5 |

- |

|

Other |

N≤ |

Al≤ |

Ti≤ |

Fe≤ |

Co≤ |

V≤ |

W≤ |

Nb≤ |

|

- |

- |

- |

2.0-6.0 |

2.50 |

0.035 |

2.50-3.50 |

- |

3. Physical properties of Hastelloy C22 (N06022) Hastelloy: Density: 8.9 g/cm3, melting point: 1325-1370 ℃

4. The minimum value of the mechanical properties of Hastelloy C22 (N06022) Hastelloy alloy at room temperature:

1. Hastelloy C22 (N06022) nickel-based alloy tensile strength Rm N/mm2: 690

2. Hastelloy C22 (N06022) nickel-based alloy yield strength RP0.2N/mm2: 283

3. Hastelloy C22 (N06022) nickel-based alloy elongation A5 %: 40

5. Hastelloy C22 (N06022) Hastelloy has the following characteristics:

Hastelloy C22 (N06022) is a versatile nickel-chromium-molybdenum-tungsten alloy with better overall corrosion resistance than other existing nickel-chromium-molybdenum alloys. The alloy has good resistance to pitting, crevice corrosion and stress. Corrosion cracking ability. It has excellent resistance to oxidative aqueous media including wet chlorine, nitric acid or a mixture of oxidative acids containing chloride ions.

6. Metallographic structure of Hastelloy C22 (N06022) Hastelloy: Hastelloy C22 alloy has a face-centered cubic lattice structure.

7. Corrosion resistance of Hastelloy C22 (N06022) Hastelloy:

Hastelloy C22 alloy is suitable for various chemical process industries containing oxidizing and reducing media. The higher molybdenum and chromium contents make the alloy resistant to chloride ions, and the tungsten element further improves its corrosion resistance. Hastelloy C22 is one of only a few materials resistant to corrosion in wet chlorine, hypochlorite, and chlorine dioxide solutions. copper chloride).

8. Hastelloy C22 (N06022) Hastelloy application range Application areas are:

Hastelloy C22 alloy is widely used in chemical and petrochemical fields, such as components and catalytic systems in contact with chloride-containing organics. This material is especially suitable for use in high temperature, inorganic and organic acids mixed with impurities (such as formic acid and acetic acid), and seawater corrosive environments.

9. Hastelloy C22 (N06022) Hastelloy other application areas:

Acetic acid/acetic anhydride, acid leaching, cellophane manufacturing, chlorination systems, complex mixed acids, rolls for electrogalvanizing baths, expansion bellows, flue gas scrubber systems, geothermal wells, hydrogen fluoride furnace scrubbers, incineration scrubber systems, nuclear fuel Regeneration, pesticide production, phosphoric acid production, pickling systems, plate heat exchangers, selective filtration systems, sulfur dioxide cooling towers, sulfonation systems, tubular heat exchangers, surfacing valves.