PRODUCT

A High-tech Enterprise Dedicated To Special Alloy Materials, Specializing In The Research And Sales Of Nickel-based, Iron-based And Other Special Alloys

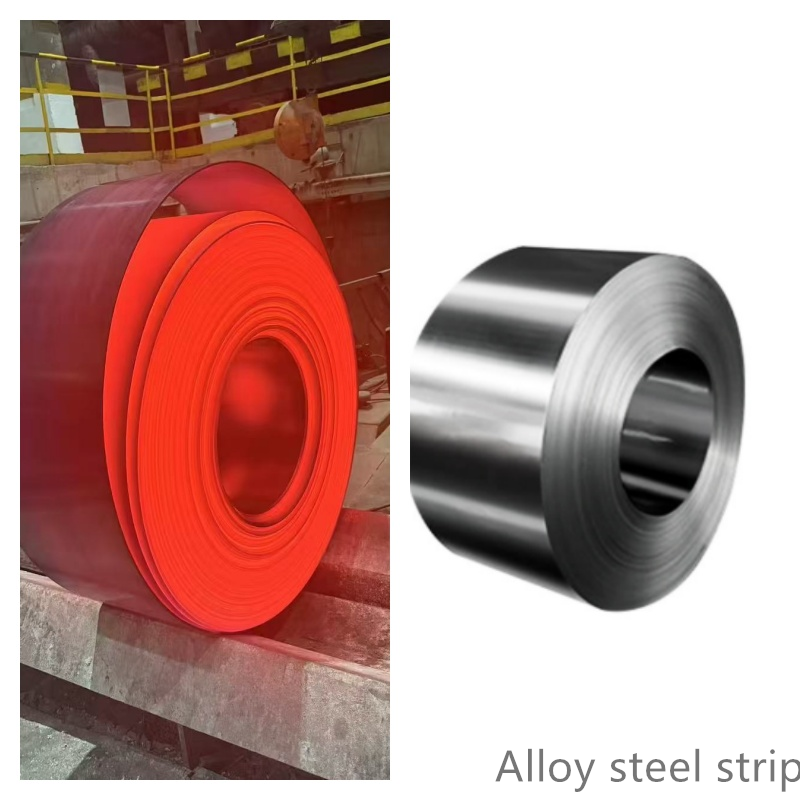

Monel 400 alloy plate UNS N04400/ 2.4360 Monel teel pipe/bar/steel strip/coil

Monel 400 (N04400) Monel alloy is a kind of corrosion resistance with the largest amount, the most widely used and excellent comprehensive performance.

HastelloyB/ Hastelloy C276/HastelloyB2 alloy plate strip/coil

Hastelloy B is a nickel-based superalloy composed of nickel, molybdenum, cobalt and other elements, with a nickel content of about 62%. Hastelloy B has a wide range of applications in the chemical, petrochemical, energy manufacturing and pollution control fields, especially in industries such as sulfuric acid, hydrochloric acid, phosphoric acid, and acetic acid.

Nickel alloy steel strip Inconel 718 plate NS341 teel pipe bar manufacturer

NS337 corrosion-resistant alloy is a high-performance nickel-based alloy with excellent corrosion resistance, high-temperature strength and good processing properties. The following are its detailed features: Chemical composition: Mainly composed of nickel, chromium, molybdenum and other elements. These elements give the alloy unique performance characteristics, such as good ductility, toughness, oxidation resistance, and corrosion resistance. Corrosion resistance: It performs well in acidic, alkaline, and chlorinated corrosion environments. It has good corrosion resistance against inorganic acids such as sulfuric acid, nitric acid, and hydrochloric acid, and can be used in seawater for a long time. High temperature performance: It can maintain good comprehensive performance in the temperature range of -253℃ to 700℃, especially its strength and stability can be maintained at high temperatures. Processing and weldability: It has good processability and weldability, and can manufacture various parts with complex shapes. Application fields: Widely used in chemical equipment, marine engineering, oil and gas and other fields, as well as desalination equipment, nuclear energy, electric power and other industries. To sum up, NS337 corrosion-resistant alloy is a high-performance material widely used in many fields

Nickel alloy Inconel 601 plate/ UNS N06601 teel bar 2.4851/alloy 601 steel strip/coil

Inconel 601 is a high-temperature alloy, mainly composed of nickel, chromium and iron, and containing elements such as aluminum and titanium. It has good high temperature resistance, oxidation resistance, corrosion resistance and mechanical properties. Chemical composition: Nickel content 61%-63%, chromium content 21%-25%, iron content 6%-10%, and also contains aluminum, titanium, silicon, manganese and other elements. Physical Properties: Density is about 8.1 g/cubic centimeter, hardness is between HB180-220. High temperature resistance: It can work at high temperatures from 1100°C to 1200°C, and has good thermal stability and thermal conductivity. Oxidation resistance and creep resistance: It can operate stably for a long time in high temperature and oxidizing environments, and has high creep rupture strength. Anti-corrosion performance: Resistant to corrosion by a variety of chemical media such as acids, alkalis, and salts. Mechanical Properties: High strength, high toughness and good plasticity. Application fields: Widely used in the manufacture of high-temperature stoves, pipes, heat exchangers, aerospace engine components, etc. Inconel 601 alloy is widely used in the petroleum, chemical, aerospace and energy industries due to its excellent properties

NS336 corrosion resistant alloy Plate,Roll,Steel belt,Great,Tube,Forging

NS336 (Inconel625, N06625, 2.4610) alloy is a solution strengthened nickel base deformed superalloy with molybdenum and niobium as the main strengthening elements.

Monel400 alloy plate Monel k-500 steel coil manufacturer

Monel 400 (N04400) Monel alloy is a kind of corrosion resistance with the largest amount, the most widely used and excellent comprehensive performance.

NS335 Corrosion resistant alloy Plate,Roll,Steel belt,Great,Tube,Forging

NS335 (Hastelloy C-4, N06645, 2.4610) alloy is an austenitic low carbon nickel-molybdenum-chromium alloy. The main difference between Nicrofer 6616 hMo and other earlier developed alloys of similar chemical composition is the low carbon, silicon, iron, and tungsten content.

Shandong Titanium Nickel Special Steel Co., Ltd.,

Shandong Titanium Nickel Special Steel Co., Ltd., with a registered capital of fifteen million eight hundred and eighty thousand yuan, is a high-tech enterprise specializing in the research and sales of nickel based, iron based and other special alloys. Its products include corrosion-resistant alloys, high-temperature alloys, precision alloys, Hastelloy alloys, Monel alloys, INCONEL, INCOLOY, copper nickel alloys, titanium and titanium alloys, zirconium and zirconium alloys, nickel and nickel based alloys, There are more than 60 kinds of alloy materials, such as nickel cobalt base heat-resistant alloy, hafnium alloy, special stainless steel, etc. On the basis of stabilizing the original product quality and according to the market demand, it has solved the quality problems existing in the traditional metallurgical process, ensured that the alloy material products are low in impurities and deflection, and has won an excellent reputation in the industry.

Quality

Solve the quality problems existing in traditional metallurgical processes

Equipment

Rich production equipment to meet customer needs

Experience

We firmly believe that we can do what others cannot; We will do better if others can.

Serve

After strict technical training, an experienced service team has been established

News

A High-tech Enterprise Dedicated To Special Alloy Materials, Specializing In The Research And Sales Of Nickel-based, Iron-based And Other Special Alloys

Application

Desulfurization and denitration of power plants, thermal power industry, aerospace, petrochemical equipment, coal chemical industry, fluorine chemical industry, fine chemical industry, PTA, environmental protection, seawater desalination, paper making machinery, pharmaceutical equipment, heat exchange equipment, electrochemistry, metallurgy, offshore platforms, nuclear energy, chlor alkali, shipbuilding, cement manufacturing, explosive compounding, acetic anhydride, salt making, medical equipment, sports and leisure, plate heat exchanger, bellows expansion joint compensator and other industries.

Desulfurization and denitration

The high nickel alloy has good corrosion resistance in the wet desulfurization unit, especially the content of chromium and molybdenum is increased, and the resistance to spot corrosion and crevice corrosion is strengthened.

Check The DetailsThe development history of low expansion superalloys is reviewed The development of "Invar effect" and "age hardening" has laid the foundation for the development of low expansion superalloys The rapid development of aerospace industry and the outbreak of energy crisis in the 1970s provided a valuable opportunity for the practical application of low expansion superalloys in aerospace industry.

Check The DetailsThe high content of Ni and Mo in C-276 alloy makes it have a strong resistance to chloride stress corrosion cracking. The following table shows the stress corrosion cracking tests of four metals in different chloride containing solutions.

Check The DetailsNickel and nickel alloys are ideal metal materials used in various harsh corrosive environments such as chemical, petroleum, non-ferrous metal smelting, high temperature, high pressure, high concentration or mixed with impurities.

Check The Details